Page 1070 - A.J. Kitchen & Service

P. 1070

Fagor Professional Foodservice | Commercial refrigeration

Blast chillers

Why use a blast chiller?

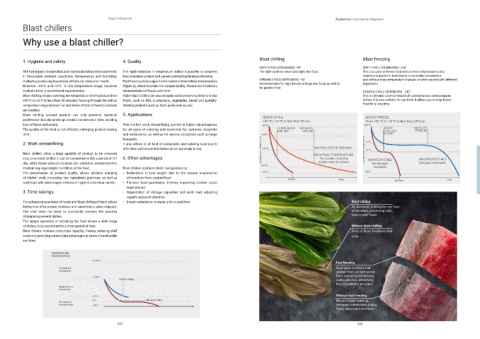

1. Hygiene and safety 4. Quality Blast chilling Blast freezing

SOFT CYCLE (STANDARD) - 90‘ SOFT CYCLE (STANDARD) - 240‘

All fresh organic food products contain a natural bacterial load which, The rapid reduction in temperature makes it possible to conserve The right cycle for small size, light, fine food. This is a cycle to freeze food with an even temperature and is

in favourable ambient conditions (temperature and humidity), food moisture content and prevent normal bacterial proliferation. therefore suitable for food that is to be cooled consistently

multiplies producing hazardous effects on consumer health. Fast freezing encourages the formation of intercellular microcrystals STRONG CYCLE (INTENSIVE) - 90‘ and without sharp temperature changes or when cooked with different

ingredients.

Recommended for high density or large size food, as well as

Between +65°C and +3°C: in this temperature range, bacterial (figure 2), which maintain the compactability, flavour and freshness for packed food.

multiplication is accelerated exponentially. characteristics of foods over time. STRONG CYCLE (INTENSIVE) - 240‘

Blast chilling means lowering the temperature of the product from Asber blast chillers are also exceptional at preserving fresh and raw This is the ideal cycle to freeze half cooked food or semi-prepared

+90°C to +3°C in less than 90 minutes Passing through the critical foods, such as fish, crustaceans, vegetables, bread and partially- dishes. It is also suitable for raw food. It allows you to keep frozen

temperature range between so fast where effects of harmful bacteria finished products such as fresh pasta and sauces. food for a long time.

are disabled.

Blast chilling cooked product not only prevents bacterial 5. Applications QUICK CHILL QUICK FREEZE

proliferation but also prolongs product conservation time, avoiding +90 ºC / +3 ºC in less than 90 min. From +90 ºC to -18 ºC in less than 240 min.

loss of flavor and aroma. This kitchen work streamlining system is highly advantageous +90 ºC +90 ºC

The quality of the food is not affected, enlarging product storing for all types of catering and especially for canteens, hospitals FAGOR BLAST NO BLAST BLAST NO BLAST

FREEZER

CHILLER

CHILLER

FREEZER

time. and restaurants, as well as for special occasions such as large +65 ºC FAGOR

banquets.

2. Work streamlining It also allows to all kind of restaurants and catering business to 0 ºC

offer their well-presented dishes which are ready to eat. COOKED FOOD TEMPERATURE +37 ºC BACTERIA FIRST APPEARANCE COOKED FOOD TEMPERATURE -5 ºC

Blast chillers allow a large quantity of product to be prepared HIGH RISK TEMPERATURE

and, once blast chilled, it can be consumed within a period of 5-7 6. Other advantages The number of bacteria MICROCRYSTALS MACROCRYSTALS

day, while frozen product duration can extend to several months, +10 ºC doubles every 20 minutes Non-damaged Damaged membranes

maintaining organoleptic condition of the food. Blast chillers optimize stock management by: membranes

The preservation of product quality, allows advance planning • Reductions in lost weight due to the natural evaporation +3 ºC -18 ºC

of kitchen work, improving raw ingredients purchase, as well as of moisture from cooked food 90 min TIME TIME

work load with advantages in terms of hygiene and menu variety. • Planned food purchases, thereby improving kitchen stock 240 min

organisation

3. Time savings • Organization of storage capacities and work load, adjusting

capable personal attention

The advance preparation of foods and blast chilling of them allows • Drastic reductions in waste and unused food Blast chilling

kitchens to offer a more delicious and varied menu when required. No bacterial proliferation nor loss

The chef does not have to constantly oversee the process of moisture, preserving color,

of preparing several dishes. texture and flavor.

The simple operation of reheating the food allows a wide range

of dishes to be served within a short period of time. Without blast chilling

Blast chillers increase production capacity, thereby reducing staff Product loses freshness and

costs and providing outstanding advantages in terms of profitability color

and time.

TEMPERATURE

Bacterial Activity

+ 120º C

Fast freezing

Destruction of Ideal cycle to freeze half

bacterial flora cooked food, as well as raw

food, microcrystal forming

+ 70º C

No Blast Chilling during process, preserving

food membrane structure.

Multiplication of

bacterial flora

+ 3º C Without fast freezing

0º C With Blast Chilling Macro crystal forming

Interruption of

bacterial activity - 18º C damages membranes losing

fluids, thus color and flavor

329 330