Page 929 - A.J. Kitchen & Service

P. 929

Fagor Professional Foodservice | Cooking

Tilting bratt pans Bain maries

- Pans filled with water by means of electric valve operated

with switch on the front of the machine. The filling pipe is

located at the back of the machine.

- Double walled lid with drainer at the back to redirect water of

condensation back into the well.

- Lid balance system by springs. Compensation system to

avoid heavy falls. Can be regulated, with the same system for

all modules.

- Micro breaking switch halts heating when the pan is raised.

- High temperature enamelled cast iron flue protector.

- Access to the components from the front.

- Machines with IPX5 grade water protection.

- Front access lid handle.

- Electrically heated models use shielded stainless steel

General characteristics heating elements located under the bottom of the pan.

- Gas heated models use steel burners with six branches

- Laser-cut joints, automatic welding and polished. (eight in the pan with one and a half modules), operated and General characteristics

- Motorised or crank operated elevation systems which controlled by safety valve with thermocouple.

raises the pan until it is vertical, to empty it completely. - Temperature of the bottom of the pan controlled by

- Versions with cast iron and stainless steel pans. thermostat, between 50 and 310 °C. - Surface tops manufactured in 2 mm thick overflow tube. - Tube for alternative manual ignition.

- Pan design with a rounded corners and no edges, and with a wide - The heating by branched burners or electrical heating AISI-304 stainless steel. - The filling tap is sold as an optional accessory.

opening for unloading, making all cooking and cleaning operations elements located in the base of the pan itself, together - Laser-cut joints, automatic welding and - Regulation of water temperature by thermostat, ELECTRIC MODELS

between 30 and 90 °C.

easier. with the high thickness of the bottom of the pan, ensure polished. - Controls with protective base and system - AISI-304 stainless steel heating elements

located on the outside of the well.

maximum uniformity of temperature distribution in all cases,

- Flange around the perimeter to stop any condensed water from guaranteeing even cooking. - Wells accommodating different against water infiltration (IPX5 grade - Safety thermostat in the electric models

spilling over. configurations of Gastronorm containers protection). - Voltage: 400 V 3+N. It can be transformed to

- The bottom of the wells is very thick (8 mm for iron pans and 10 mm VOLTAGE FOR ELECTRIC MODELS: of different sizes, 150 mm high and with - High temperature enamelled cast iron flue other voltages..

dimensions:

protector.

for stainless steel pans), guaranteeing even heat distribution. - 400 V 3+N - Ask for other voltages.

· Half module: GN-1/1+1/3, with 22 litres - Access to the components from the front.

capacity. - Machines with IPX5 grade water protection. OPTIONAL ACCESSORIES

· One module: GN-2/1+(2x1/3), with 44 litres (see accessories page at end of chapter)

capacity. GAS MODELS - Simple tap to install at the back of the bain

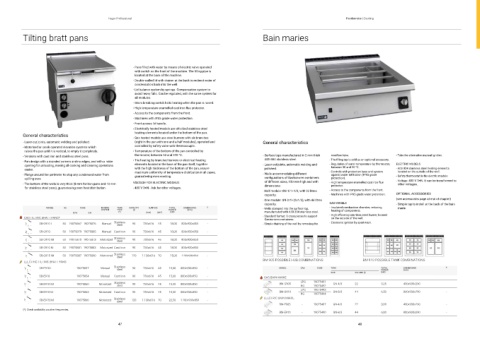

MODEL HZ. CODE RAISING TANK CAPACITY SURFACE TOTAL DIMENSIONS € - Wells stamped into the surface top, - Insulated combustion chamber, reducing marie.

SYSTEM TYPE (l) POWER (mm) heating of components.

LPG GN (*) (mm) (dm 2 ) (kW) manufactured with AISI-304 stainless steel.

- Standard format: 3 crosspieces to support - High efficiency stainless steel burner, located

GAS TILTING BRATT PANS* Gastronorm containers. on the outside of the well.

SB-G910 I 50 19075867 19075876 Manual Stainless 90 730x616 45 18,00 800x930x850 - - Simple draining of the well by removing the - Electronic ignition by spark train.

steel

SB-G910 50 19075879 19075885 Manual Cast Iron 90 730x616 45 18,00 800x930x850 -

SB-G910 IM 50 19075870 19075873 Motorized Stainless 90 730x616 45 18,00 800x930x850 -

steel

SB-G910 M 50 19075881 19075883 Motorized Cast Iron 90 730x616 45 18,00 800x930x850 -

SB-G915 IM 50 19075887 19075890 Motorized Stainless 120 1.130x616 70 25,00 1.200x930x850 -

steel

ELECTRIC TILTING BRATT PANS BM 905 POSSIBLE HUB COMBINATIONS BM 910 POSSIBLE TANK COMBINATIONS

SB-E910 I 19075857 Manual Stainless 90 730x616 45 15,00 800x930x850 - MODEL GAS CODE TANK TOTAL DIMENSIONS €

steel

POWER

(mm)

SIZE VOLUME (l) (kW)

SB-E910 19075854 Manual Cast Iron 90 730x616 45 15,00 800x930x850 - GAS BAIN MARIE

SB-E910 IM 19075860 Motorized Stainless 90 730x616 45 15,00 800x930x850 - BM-G905 LPG 19075491 GN-4/3 22 3,25 400x930x290 -

steel

19075492

NG

LPG 19075493

SB-E910 M 19075863 Motorized Cast Iron 90 730x616 45 15,00 800x930x850 - BM-G910 NG 19075494 GN-8/3 44 6,50 800x930x290 -

SB-E915 IM 19075866 Motorized Stainless 120 1.130x616 70 22,50 1.200x930x850 - ELECTRIC BAIN MARIE

steel

BM-E905 - 19075487 GN-4/3 22 3,00 400x930x290 -

(*): Check availability on other frequencies.

BM-E910 - 19075490 GN-8/3 44 6,00 800x930x290 -

47 48