Page 943 - A.J. Kitchen & Service

P. 943

Fagor Professional Foodservice | Cooking

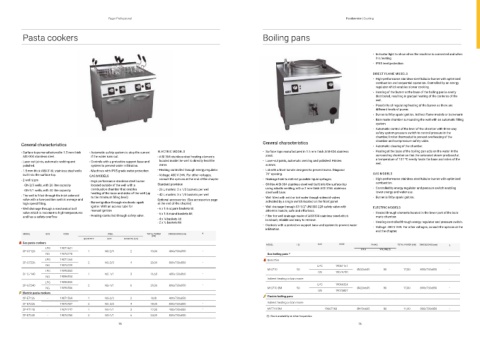

Pasta cookers Boiling pans

- Indicator light to show when the machine is connected and when

it is heating.

- IPX5 level protection.

DIRECT FLAME MODELS

- High-performance stainless-steel tubular burner with optimised

combustion and sequential operation. Controlled by an energy

regulator which enables slower cooking.

- Heating of the burner at the base of the boiling pan is evenly

distributed, resulting in gradual heating of the contents of the

well.

- Possibility of regulating heating of the burner as there are

different levels of power.

- Burner is lit by spark ignition. Indirect flame models or bain-marie

- Bain-marie chamber surrounding the well with an automatic filling

system

- Automatic control of the level of the chamber with three-way

safety system pressure switch to control pressure in the

chamber, limiter thermostat to prevent overheating of the

chamber and overpressure safety valve.

General characteristics General characteristics - Automatic clearing of the chamber.

- Surface tops manufactured in 1.5 mm thick - Automatic safety system to stop the current ELECTRIC MODELS - Surface tops manufactured in 1.5 mm thick AISI-304 stainless - Heating at the base of the boiling pan acts on the water in the

AISI-304 stainless steel. if the water runs out. - AISI 304 stainless-steel heating elements steel. surrounding chamber so that the saturated steam produced at

- Laser-cut joints, automatic welding and - Controls with a protective support base and located inside the well to directly heat the - Laser-cut joints, automatic welding and polished. Hidden a temperature of 107 ºC evenly heats the base and sides of the

well.

polished. system to prevent water infiltration. water. screws.

- 1.5 mm thick AISI-316L stainless steel wells - Machines with IPX5 grade water protection. - Heating controlled through energy regulator. - Lid with a front handle designed to prevent burns. Diagonal

built into the surface top. GAS MODELS - Voltage: 400 V 3+N. For other voltages, 70° opening. GAS MODELS

- 2 well sizes - High-performance stainless-steel burner consult the options at the end of the chapter. - Drainage hole to redirect possible liquid spillages. - High-performance stainless-steel tubular burner with optimised

· GN-2/3 wells, with 26 litre capacity located outside of the well with a Standard provision - 80-litre AISI-304 stainless-steel well built into the surface top combustion.

· GN-1/1 wells, with 40 litre capacity combustion chamber that enables - 26 L models: 2 x 1/3 baskets per well using robotic welding, with a 2 mm-thick AISI 316L stainless - Controlled by energy regulator and pressure switch enabling

lower energy and water use.

steel well base.

- The well is filled through the inlet solenoid heating of the base and sides of the well (up - 40 L models: 3 x 1/3 baskets per well - Well filled with cold or hot water though solenoid valves - Burner is lit by spark ignition.

to the minimum filling level)

valve with a two-position switch: average and Optional accessories: (See accessories page activated by a single switch located on the front panel.

high-speed filling. - Burner ignition through electronic spark at the end of the chapter)

- Well drainage through a mechanical ball igniter. With an access tube for - 6 x 1/6 square baskets kit - Well drainage through G1-1/2” UNI ISO 228 safety valve with ELECTRIC MODELS

manual ignition

athermic handle, safe and effortless.

valve which is resistant to high temperatures - 6 x 1/6 round baskets kit - Heated through elements located in the lower part of the bain-

and has a safety overflow. - Heating controlled through safety valve. - Filter for well drainage made of AISI-304 stainless-steel which marie chamber.

- 4 x ¼ baskets kit is robust, reliable and easy to remove.

- 2 x ½ baskets kit - Heating controlled through energy regulator and pressure switch.

- Controls with a protective support base and system to prevent water - Voltage: 400 V 3+N. For other voltages, consult the options at the

infiltration. end the chapter.

MODEL GAS CODE WELL TOTAL POWER DIMENSIONS (mm) €

(kW)

QUANTITY SIZE BASKETS (1/3)

Gas pasta cookers

MODEL HZ GAS CODE TANKS TOTAL POWER (kW) DIMENSIONS (mm) €

LPG 19071621 D X H VOLUME (l)

CP-G7126 1 NG-2/3 2 10,00 400x730x850 -

NG 19074728 Gas boiling pans *

LPG 19071360 Direct fire

CP-G7226 2 NG-2/3 4 20,00 800x730x850 -

NG 19074729 LPG 19061151

LPG 19098553 M-G710 50 GN 19074790 Ø420x605 80 17,00 800x730x850 -

CP-G7140 1 NG-1/1 3 16,50 400x730x850 -

NG 19098554

Indirect heating or bain marie

LPG 19098555

CP-G7240 2 NG-1/1 6 33,00 800x730x850 - LPG 19066324

NG 19098556 M-G710 BM 50 Ø420x605 80 17,00 800x730x850 -

Electric pasta cookers GN 19074807

CP-E7126 - 19071569 1 NG-2/3 2 9,00 400x730x850 - Electric boiling pans

CP-E7226 - 19072437 2 NG-2/3 4 18,00 800x730x850 - Indirect heating or bain marie

CP-E7140 - 19074747 1 NG-1/1 3 12,00 400x730x850 - M-E710 BM - 19067268 Ø420x605 80 11,00 800x730x850 -

CP-E7240 - 19074780 2 NG-1/1 6 24,00 800x730x850 - (*): Check availability on other frequencies.

75 76