Page 965 - A.J. Kitchen & Service

P. 965

Fagor Professional Foodservice | Cooking

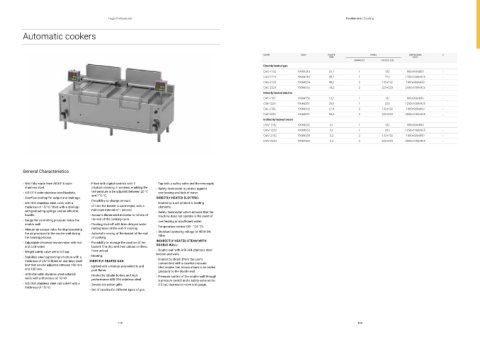

Automatic cookers

MODEL CODE POWER TANKS DIMENSIONS €

(kW) (mm)

QUANTITY CAPACITY (l)

Directly heated gas

CAG-1132 19084248 24,1 1 132 900x900x850 -

CAG-1223 19084249 39,1 1 223 1250x1000x925 -

CAG-2132 19084254 48,2 2 132+132 1800x900x850 -

CAG-2223 19084255 78,2 2 223+223 2500x1000x925 -

Directly heated electric

CAE-1132 19084250 13,7 1 132 900x900x850 -

CAE-1223 19084251 25,0 1 223 1250x1000x925 -

CAE-2132 19084256 27,4 2 132+132 1800x900x850 -

CAE-2223 19084257 50,0 2 223+223 2500x1000x925 -

Indirectly heated steam

CAIV-1132 19084252 0,1 1 132 900x900x850 -

CAIV-1223 19084253 0,1 1 223 1250x1000x925 -

CAIV-2132 19084258 0,2 2 132+132 1800x900x850 -

CAIV-2223 19084260 0,2 2 223+223 2500x1000x925 -

General Characteristics

- Well fully made from AISI-316 satin - Fitted with digital controls with 3 - Tap with a safety valve and thermocouple.

stainless steel. displays showing 4 numbers, enabling the - Safety thermostat to protect against

- AISI-316 satin stainless steel baskets. temperature to be adjusted between 20 °C overheating and lack of water.

- Overflow and tap for output and drainage. and 110 °C. DIRECTLY HEATED ELECTRIC:

- AISI-304 stainless steel cover with a - Possibility to change amount - Heated by a set of electric heating

thickness of 15/10, fitted with a steel zip of time the basket is submerged, with a elements.

with preloading springs and an athermic minimum interval of 1 second. - Safety thermostat which ensures that the

handle. - Acoustic illuminated indicator to inform of machine does not operate in the event of

- Gauge for controlling pressure inside the the end of the cooking cycle. overheating or insufficient water.

double wall. - Cooking shut-off with time delayed water - Temperature control (50 - 120 °C).

- Manual air escape valve for depressurising reintegration at the end of cooking.

the air produced in the double wall during - Automatic raising of the basket at the end - Standard operating voltage of 400V-3N-

the heating process. of cooking. 50Hz

- Adjustable chromed bronze mixer with hot - Possibility to manage the position of the INDIRECTLY HEATED STEAM WITH

and cold water. basket: first drip and then unload or direct DOUBLE WALL:

- Weight safety valve set to 0.5 bar. front unload. - Double wall with AISI-304 stainless steel

bottom and walls.

- Stainless steel supporting structure with a - Heating: - Heated by steam (from the user’s

thickness of 20/10 fitted on stainless steel DIRECTLY HEATED GAS: connection) with a counter-pressure

feet that can be adjusted between 150 mm - Ignited with a manual piezoelectric and electrovalve that allows steam to be added

and 180 mm. pilot flame. gradually to the double wall.

- AISI-304 satin stainless steel external - Heated by tubular boilers and high- - Pressure control of the double wall through

walls with a thickness of 10/10. performance AISI-304 stainless steel. a pressure switch and a safety valve set to

- AISI-304 stainless steel satin shelf with a - Smoke extraction grille. 0.5 bar, depression valve and gauge.

thickness of 15/10.

- Set of nozzles for different types of gas.

119 120