Page 961 - A.J. Kitchen & Service

P. 961

Fagor Professional Foodservice | Cooking

Fixed Gastronorm rectangular boiling pans

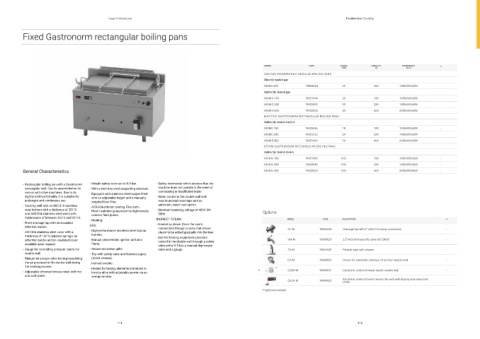

MODEL CODE POWER CAPACITY DIMENSIONS €

(kW) (l) (mm)

GAS GASTRONORM RECTANGULAR BOILING PANS

Directly heated gas

MGNG-280 19084264 35 280 1400x900x850 -

Indirectly heated gas

MGNIG-180 19001394 29 180 1000x900x850 -

MGNIG-280 19003083 35 280 1400x900x850 -

MGNIG-400 19003084 45 400 2000x900x850 -

ELECTRIC GASTRONORM RECTANGULAR BOILING PANS

Indirectly heated electric

MGNIE-180 19003046 18 180 1000x900x850 -

MGNIE-280 19001312 24 280 1400x900x850 -

MGNIE-400 19001393 36 400 2000x900x850 -

STEAM GASTRONORM RECTANGULAR BOILING PANS

Indirectly heated steam

MGNIV-180 19001396 0.05 180 1000x900x850 -

MGNIV-280 19003049 0.05 280 1400x900x850 -

General Characteristics MGNIV-400 19003050 0.05 400 2000x900x850 -

- Rectangular boiling pan with a Gastronorm - Weight safety valve set to 0.5 bar. - Safety thermostat which ensures that the

rectangular well. Can be assembled on its - With a stainless steel supporting structure. machine does not operate in the event of

own or with other machines. Due to its - Equipped with stainless steel support feet overheating or insufficient water.

rigidity and functionality, it is suitable for with an adjustable height and a manually - Water control in the double wall with

prolonged and continuous use. emptied liner filter. maximum/minimum taps and an

- Cooking well with an AISI-316 stainless - AISI-304 exterior coating. Fine satin. automatic water load option.

steel bottom with a thickness of 25/10 Heat insulation guaranteed by high-density - Standard operating voltage of 400V-3N-

and AISI-304 stainless steel walls with ceramic fibre plates. 50Hz Options

thicknesses of between 20/10 and 25/10. - Heating: INDIRECT STEAM: MODEL CODE DESCRIPTION €

- Front drainage tap with an insulated - Heated by steam (from the user’s

athermic handle. GAS: connection) through a valve that allows GF-M 19084528 Drainage tap with 2” AISI-316 clamp connection -

- AISI-304 stainless steel cover with a - High-performance stainless-steel tubular steam to be added gradually into the liner.

thickness of 15/10, balance springs, an burners. - Indirect heating equipment: pressure

athermic handle and an insulated cover - Manual piezoelectric ignition and pilot control in the double wall through a safety VM-M 19084529 2.5” AISI-304 butterfly valve ISO DN50 -

available upon request. flame. valve set to 0.5 bar, a manual depression

- Gauge for controlling pressure inside the - Smoke extraction grille. valve and a gauge. TD-M 19084539 Flexible tube with shower -

double wall. - Tap with safety valve and thermocouples

- Manual air escape valve for depressurising (direct version). DA-M 19084530 Device for automatic drainage of air from double wall -

the air produced in the double wall during . Indirect electric:

the heating process. - Heated by heating elements immersed in

- Adjustable chromed bronze mixer with hot Incoloy alloy with adjustable power via an * CENA-M 19084531 Electronic control of water load in double wall -

and cold water. energy variator.

CECA-M 19084532 Electronic control of water load in the well with display and volumetric -

probe

* Highly recomended

111 112