Page 1099 - A.J. Kitchen & Service

P. 1099

Fagor Professional Foodservice | Distribution

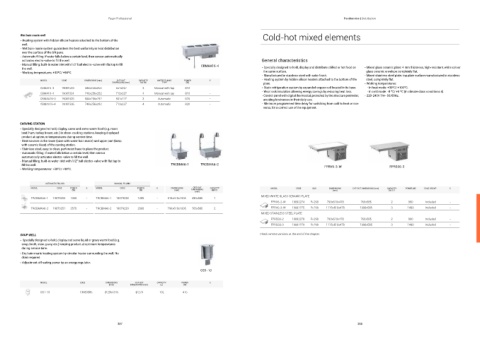

Wet bain marie well Cold-hot mixed elements

- Heating system with hidden silicon heaters attached to the bottom of the

well.

- Wet bain-marie system guarantees the best uniformity in heat distribution

over the surface of the GN pans.

- Automatic filling: if water falls below a certain level, then sensor automatically

activates electro-valve to fill the well. General characteristics

- Manual filling: built-in water inlet with 1/2” ball electro-valve with flat tap to fill CBMAA16-4

the well. - Specially designed to hold, display and distribute chilled or hot food on - Mixed glass ceramic plate: 4 mm thickness, high-resistant, white colour

- Working temperatures: +30ºC/ +90ºC. the same surface. glass ceramic envelope completely flat.

- Manufactured in stainless steel with satin finish. - Mixed stainless steel plate: top plate surface manufactured in stainless

MODEL CODE DIMENSIONS (mm) CUT-OUT CAPACITY WATER FILLING POWER € - Heating system by hidden silicon heaters attached to the bottom of the steel, completely flat.

DIMENSIONS (mm) GN 1/6 TYPE (W) plate. - Working temperatures:

CBMA16-3 19081533 584x256x252 551x227 3 Manual with tap 810 - - Static refrigeration system by expanded copper coil located in its base. · In heat mode: +30ºC/ +100ºC.

- Wool rock insulation allowing energy savings by reducing heat loss. · In cold mode: -8 ºC/ +5 ºC (In climate class conditions 4).

CBMA16-4 19081534 746x256x252 713x227 4 Manual with tap 810 -

- Control panel with digital thermostat, protected by the structure perimeter, - 220-240V 1N~ 50/60Hz.

CBMAA16-3 19081535 584x256x292 551x227 3 Automatic 820 - avoiding hindrances in their daily use.

CBMAA16-4 19081536 746x256x292 713x227 4 Automatic 820 - - Minimum programmed time delay for switching from cold to heat or vice

versa, for a correct use of the equipment.

CARVING STATION

- Specially designed to hold, display, carve and serve warm food (e.g. roast

beef, ham, turkey breast, etc.) in show-cooking stations, keeping displayed

product at optimum temperatures during service time.

- Heat sources in the lower (base with water bain marie) and upper part (lamp

with ceramic Heat) of the carving station.

- Stainless steel, easy to clean, perforated base to place the product.

- Automatic filling: if water falls below a certain level, then sensor

automatically activates electro-valve to fill the well.

- Manual filling: built-in water inlet with 1/2” ball electro-valve with flat tap to

fill the well. TRCBMA6-1 TRCBMA6-2 FPRV6-3-W FPRSS6-3

- Working temperatures: +30ºC/ +90ºC.

AUTOMATIC FILLING MANUAL FILLING

MODEL CODE POWER € MODEL CODE POWER € DIMENSIONS CUT-OUT CAPACITY MODEL CODE GAS DIMENSIONS CUT-OUT DIMENSIONS (mm) CAPACITY POWER (W) COLD GROUP €

(W) (W) (mm) DIMENSIONS GN 1/1 (mm) GN 1/1

(mm)

MIXED WHITE GLASS CERAMIC PLATE

TRCBMAA6-1 19079250 1300 - TRCBMA6-1 19079228 1285 - 515x610x1005 490x585 1

FPRV6-2-W 19092274 R-290 790x610x478 765x585 2 990 Included -

TRCBMAA6-2 19079251 2575 - TRCBMA6-2 19079229 2560 - 790x610x1005 765x585 2 FPRV6-3-W 19092275 R-290 1115x610x478 1090x585 3 1490 Included -

MIXED STAINLESS STEEL PLATE

FPRSS6-2 19092278 R-290 790x610x478 765x585 2 990 Included -

FPRSS6-3 19092279 R-290 1115x610x478 1090x585 3 1490 Included -

SOUP WELL Check remote versions at the end of the chapter.

- Specially designed to hold, display and serve liquid or gravy warm food (e.g.

soup, broth, stew, gravy, etc.) keeping product at optimum temperatures

during service time.

- Dry bain-marie heating system by circular heater surrounding the well. No

drain required.

- Adjustment of heating power by an energy regulator.

OS1-10

MODEL CODE DIMENSIONS CUT-OUT CAPACITY POWER €

(mm) DIMENSIONS (mm) (L) (W)

OS1-10 19083985 Ø 295X315 Ø 276 10L 475 -

387 388