Page 958 - A.J. Kitchen & Service

P. 958

Fagor Professional Foodservice | Cooking

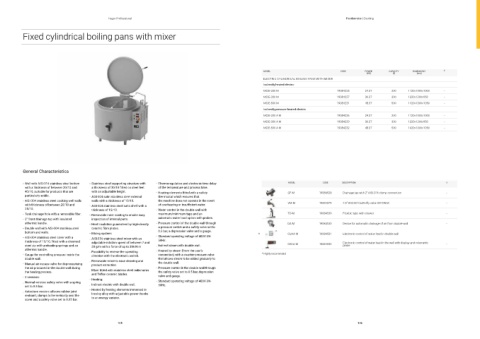

Fixed cylindrical boiling pans with mixer

MODEL CODE POWER CAPACITY DIMENSIONS €

(kW) (l) (mm)

ELECTRIC CYLINDRICAL BOILING PANS WITH MIXER

Indirectly heated electric

MCIE-200 M 19084225 24.37 200 1120x1000x1000 -

MCIE-300 M 19084227 36.37 300 1320x1200x950 -

MCIE-500 M 19084231 48.37 500 1420x1300x1050 -

Indirectly pressure heated electric

MCIE-200 A M 19084226 24.37 200 1120x1000x1000 -

MCIE-300 A M 19084229 36.37 300 1320x1200x950 -

MCIE-500 A M 19084232 48.37 500 1420x1300x1050 -

General Characteristics

- Well with AISI-316 stainless steel bottom - Stainless steel supporting structure with - Thermoregulation and electronic time delay MODEL CODE DESCRIPTION €

with a thickness of between 20/10 and a thickness of 30/10 fitted on steel feet of the temperature and process time.

40/10, suitable for products that are with an adjustable height. - Heating elements fitted with a safety GF-M 19084528 Drainage tap with 2” AISI-316 clamp connection -

particularly acidic. - AISI-304 satin stainless steel external thermostat which ensures that

- AISI-304 stainless steel cooking well walls walls with a thickness of 10/10. the machine does not operate in the event

with thickness of between 20/10 and - AISI-304 stainless steel satin shelf with a of overheating or insufficient water. VM-M 19084529 2.5” AISI-304 butterfly valve ISO DN50 -

25/10. thickness of 15/10. - Water control in the double wall with

- Tank drainage hole with a removable filter. - Removable inner coating to enable easy maximum/minimum taps and an TD-M 19084539 Flexible tube with shower -

- 2” front drainage tap with insulated inspection of internal parts. automatic water load option with probes.

athermic handle. - Heat insulation guaranteed by high-density - Pressure control of the double wall through DA-M 19084530 Device for automatic drainage of air from double wall -

- Double wall with AISI-304 stainless steel ceramic fibre plates. a pressure switch and a safety valve set to

bottom and walls. - Mixing system: 0.5 bar, a depression valve and a gauge. * CENA-M 19084531 Electronic control of water load in double wall -

- AISI-304 stainless steel cover with a . AISI-316 stainless steel mixer with an - Standard operating voltage of 400V-3N-

thickness of 15/10, fitted with a chromed adjustable rotation speed of between 7 and 50Hz. Electronic control of water load in the well with display and volumetric

steel zip with preloading springs and an 28 g/m with a force of up to 386 N·m . Indirect steam with double wall. CECA-M 19084532 probe -

athermic handle. . Possibility to reverse the operating - Heated by steam (from the user’s

- Gauge for controlling pressure inside the direction with the electronic switch. connection) with a counter-pressure valve * Highly recomended

double wall. . Removable mixer to ease cleaning and that allows steam to be added gradually to

- Manual air escape valve for depressurising product extraction. the double wall.

the air produced in the double wall during - Pressure control in the double wall through

the heating process. . Mixer fitted with stainless steel radial arms the safety valve set to 0.5 bar, depression

and Teflon ceramic blades.

- 2 versions: - Heating: valve and gauge.

. Normal version: safety valve with a spring . Indirect electric with double wall. - Standard operating voltage of 400V-3N-

set to 0.5 bar. 50Hz.

. Autoclave version: silicone rubber joint - Heated by heating elements immersed in

restraint, clamps to hermetically seal the Incoloy alloy with adjustable power thanks

cover and a safety valve set to 0.05 bar. to an energy variator.

105 106