Page 2276 - A.J. Kitchen & Service

P. 2276

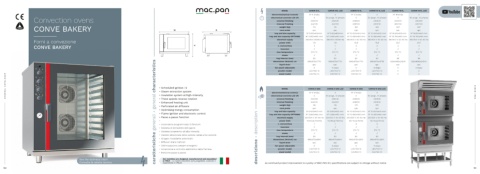

model CONVE 5 EL CONVE 5 EL LCD CONVE 10 EL CONVE 10 EL LCD CONVE 16 EL CONVE 16 EL LCD

electromechanical controls N° 4 knobs X N° 4 knobs X N° 4 knobs X

Convection ovens electronical controls LCD (P) AISI430 90 progr., 10 phases AISI430 90 progr., 10 phases AISI430 90 progr., 10 phases

X

X

X

AISI430

AISI430

AISI430

external finishing

CONVE BAKERY W D internal finishing Aisi430 Aisi430 AISI430 AISI430 AISI430 AISI430

110

162

337

weight (Kg)

110

162

337

opt.

core probe

opt.

opt.

opt.

opt.

opt.

tray and size capacity N° 5 600x400mm N° 5 600x400mm N° 10 600x400 mm N° 10 600x400 mm N° 16 600x400 mm N° 16 600x400 mm

tray and size capacity OPTIONAL N° 5 660x460 mm N° 5 660x460 mm N° 10 660x460 mm N° 10 660x460 mm N° 16 760x460 mm N° 16 760x460 mm

Forni a convezione electrical supply 380/400 V5060 Hz 380/400 V5060 Hz 380/400 V 50-60 Hz 380/400 V 50-60 Hz 380/400 V 50-60 Hz 380/400 V 50-60 Hz

power (kW)

23,7

15,8

7,9

15,8

7,9

23,7

CONVE BAKERY H n. motors/fans √ 1 √ 1 2 √ 2 √ 3 √ 3 √

inversion

max temperature 270 °C 270 °C 270 °C 270 °C 270 °C 270 °C

steam √ √ √ √ √ √

tray interval (mm) 80 80 80 80 88 88

caratteristiche generali • general characteristics

dimensions (WxDxH) cm 995x975x777h 995x975x777h 995x975x1177h 995x975x1177h 925x1695x2150h 925x1695x2150h

liquid drain opt. opt. opt. opt. opt. opt.

fan speed adjustable X 3 steps X 3 steps X 3 steps

proofer model LIEVTEK 10 LIEVTEK 10 LIEVTEK 10 LIEVTEK 10 X X X X

CAVTEK 10

CAVTEK 10

CAVTEK 10

stand model

CAVTEK 10

GENERAL CA T AL OGUE • Scheduled ignition | 5 electromechanical controls CONVE 5 GAS CONVE 5 GAS LCD CONVE 10 GAS CONVE 10 GAS LCD SINCE 198 3

model

• Steam extraction system

X

N° 4 knobs

X

N° 4 knobs

• Insulation system at high-intensity

X

X

• Three speeds reverse rotation

AISI430

AISI430

external finishing

Aisi430

AISI430

AISI430

Aisi430

internal finishing

• Enhanced heating unit electronical controls LCD (P) AISI430 90 progr., 10 phases AISI430 90 progr., 10 phases

• Perforated air diffusers weight (Kg) 115 115 172 172

opt.

opt.

opt.

core probe

opt.

• Optimising energy consumption tray and size capacity N° 5 600x400 mm N° 5 600x400 mm N° 10 600x400 mm N° 10 600x400 mm

• Flame ignition and electronic control tray and size capacity OPTIONAL N° 5 660x460 mm N° 5 660x460 mm N° 10 660x460 mm N° 10 660x460 mm

• Passo a passo function electrical supply 220/230 V 50-60 Hz 220/230 V 50-60 Hz 220/230 V 50-60 Hz 220/230 V 50-60 Hz

• power (kW) 11,6 Kcal/13,8 Kw 11,6 Kcal/13,8 Kw 13,7 Kcal/16 Kw 13,7 Kcal/16 Kw

• Accensione programmata | 5 funzioni n. motors/fans 1 1 2 2

• Sistema di estrazione del vapore inversion √ √ √ √

• Sistema isolamento ad alta intensità max temperature 270 °C 270 °C 270 °C 270 °C

steam

√

√

√

√

• Cambio direzionale delle ventole radiali a tre velocità tray interval (mm) 80 80 80 80

• Gruppo riscaldante potenziato descrizione • description dimensions (WxDxH) cm 995x975x881h 995x975x881h 995x975x1281h 995x975x1281h

• Diffusori d'aria traforati liquid drain opt. opt. opt. opt.

• Ottimizzazione consumi energetici fan speed adjustable X 3 steps X 3 steps

• Accensione e controllo elettronico della fiamma proofer model LIEVTEK 10 LIEVTEK 10 LIEVTEK 10 LIEVTEK 10

• Funzione passo a passo stand model CAVTEK 10 CAVTEK 10 CAVTEK 10 CAVTEK 10

See the technical chart Our machines are designed, manufactured and assembled

in ITALY. - Le nostre macchine sono progettate, costruite e

Consulta la tabella tecnica assemblate in ITALIA. As continued product improvement is a policy of MAC.PAN Srl, specifications are subject to change without notice.

150 151