Page 2297 - A.J. Kitchen & Service

P. 2297

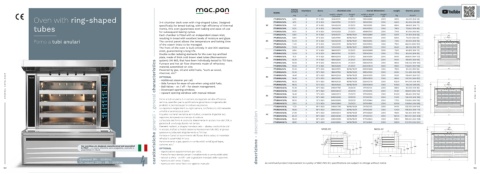

baking chambers doors chambers size overall dimensions weight thermic power

model surface n° n° width x depth height width x depth height Kg Kcal/h

mq

Oven with ring-shaped 3-4 chamber deck oven with ring-shaped tubes. Designed FTUB120/3/1L 5.00 3 3 6° X 620 1240X1790 21/21/21 1930X2680 2300 5800 60.300 (KW 69)

cm

AxB=mm

cm

CxD=mm

1240X1370

45.000 (KW 52)

2300

6400

21/21/21

6.70

6° X 620

FTUB120/3/2L

1930X3100

tubes specifically for bread-baking, with high efficiency of thermal 3C FTUB120/3/3L 7.40 3 3 6° X 620 1240X2000 21/21/21 1930X3310 2300 6800 66.600 (KW 77)

73.800 (KW 85)

inertia, this oven guarantees even baking and ease-of-use

21/21/21

7400

1930X3520

FTUB120/3/4L

2300

6° X 620

8.20

1240X2210

for subsequent baking cycles.

1939X3730

21/21/21

7700

1240X1370

8° X 620

2300

FTUB120/4/1L

54.400 (KW 62)

6.80

Each chamber is fitted with an independent steam inlet, FTUB120/3/5L 9.00 3 4 6° X 620 1240X2420 18/18//18/21 1930X2680 2300 6300 81.000 (KW 94)

resulting in bread with excellent levels of moisture and glaze. FTUB120/4/2L 8.90 4 8° X 620 1240X1790 18/18//18/21 1930X3100 2300 6800 71.200 (KW 82)

Forno a tubi anulari The control panel allows the temperature and baking time 4C FTUB120/4/3L 10.00 4 8° X 620 1240X2000 18/18//18/21 1930X3310 2300 7300 80.000 (KW 93)

of the steam inlets to be managed. FTUB120/4/4L 11.00 4 8° X 620 1240X2210 18/18//18/21 1930X3520 2300 7500 88.000 (KW 102)

The front of the oven is built entirely in aIsI 304 stainless FTUB120/4/5L 12.00 4 8° X 620 1240X2420 18/18//18/21 1939X3730 2300 8000 96.000 (KW 111)

steel, guaranteeing a long life. FTUB180/3/1L 8.90 3 9° X 620 1860X1370 21/21/21 2550X2680 2300 7200 60.800 (KW 70)

Double outlet radiating elements for the oven top and bed FTUB180/3/2L 10.00 3 9° X 620 1860X1790 21/21/21 2550X3100 2300 7700 80.000 (KW 93)

plate, made of thick cold drawn steel tubes (Mannesmann 3C FTUB180/3/3L 11.10 3 9° X 620 1860X2000 21/21/21 2550X3310 2300 8000 88.800 (KW 103)

system) UNI 663, that have been individually tested to 700 bars. FTUB180/3/4L 12.30 3 9° X 620 1860X2210 21/21/21 2550X3520 2300 9000 98.400 (KW 114)

caratteristiche generali • general characteristics

Furnace and hot air flow channels made of refractory FTUB180/3/5L 13.50 3 9° X 620 1860X2420 21/21/21 2550X3730 2300 9500 108.000 (KW 125)

material assembled on site. FTUB180/3/6L 14.50 3 9° X 620 1860X2630 21/21/21 2550X3940 2300 9800 116.800 (KW 136)

Powered by gas, oil and solid fuels, “such as wood, FTUB180/4/1L 10.20 4 12° X 620 1860X1370 18/18//18/21 2550X2680 2300 7800 81.000 (KW 94)

2550X3100

1860X1790

charcoal, etc.” 4C FTUB180/4/2L 13.30 4 4 4 12° X 620 1860X2000 18/18//18/21 2550X3520 2300 8000 104.400 (KW 121)

GENERAL CA T AL OGUE - Additional steamer per cell. FTUB180/4/5L 18.00 4 4 3 3 3 12° X 620 1860X2420 18/18//18/21 2550X3730 2300 10200 144.000 (KW 167) SINCE 198 3

12° X 620

14.40

18/18//18/21

118.400 (KW 137)

9000

FTUB180/4/3L

2550X3310

2300

OPTIONAL

2300

FTUB180/4/4L

18/18//18/21

1860X2210

12° X 620

9500

131.200 (KW 152)

16.40

- Side furnace for ease-of-use when using solid fuels.

10900

156.000 (KW 81)

2300

2550X3940

1860X2630

FTUB180/4/6L

18/18//18/21

12° X 620

19.50

- Ball Valves - on / off - for steam management.

8800

21/21/21

3170X3100

2300

80.000 (KW 93)

2480X1790

12° X 620

FTUB240/3/2L

13.30

- Downward opening windows.

14.80

21/21/21

FTUB240/3/3L

2300

9460

88.800 (KW 103)

3170X3310

12° X 620

2480X2000

- Upward opening windows with manual release

12° X 620

FTUB240/3/4L

3170X3520

2480X2210

98.400 (KW 114)

16.40

21/21/21

10000

2300

11000

Forno a tubi anulari a 3-4 camere sovrapposte ad alta efficienza

11700

FTUB240/3/6L

19.50

2300

21/21/21

2480X2630

12° X 620

116.800 (KW 136)

3170X3940

termica, specifico per la panificazione garantisce omogeneità del 3C FTUB240/3/5L 18.00 3 3 3 12° X 620 2480X2420 21/21/21 3170X3730 2300 12000 106.000 (KW 125)

2480X2840

116.800 (KW 136)

2300

21.10

21/21/21

3170X4150

FTUB240/3/7L

12° X 620

prodotto e prontezza per le cotture successive. FTUB240/4/2L 17.70 4 16° X 620 2480X1790 18/18//18/21 3170X3100 2300 9400 132.700 (KW 154)

Le vaporiere indipendenti su ogni camera, conferiscono ottimamente

umidità e lucentezza al pane. FTUB240/4/3L 19.80 4 16° X 620 2480X2000 18/18//18/21 3170X3310 2300 10400 148.500 (KW 172)

Il quadro comandi semplice ed intuitivo, consente di gestire luci, 4C FTUB240/4/4L 21.90 4 16° X 620 2480X2210 18/18//18/21 3170X3520 2300 11200 164.300 (KW 190)

vaporiere, temperatura e tempo di cottura. FTUB240/4/5L 24.00 4 16° X 620 2480X2420 18/18//18/21 3170X3730 2300 12000 180.000 (KW 208)

La facciata del forno è costruita interamente in acciaio inox aIsI 304, a FTUB240/4/6L 26.00 4 16° X 620 2480X2630 18/18//18/21 3170X3940 2300 12800 195.000 (KW 226)

garanzia di una lunga durata nel tempo. FTUB240/4/7L 28.10 4 16° X 620 2480X2840 18/18//18/21 3170X4150 2300 13200 210.700 (KW 244)

Elementi radianti, a doppia mandata cielo – platea, costituiti da tubi

in acciaio, trafilati a freddo (sistema Manessman) UNI 663, di grosso MOD.3C MOD.4C

spessore e,collaudati singolarmente a 700 bar.

Fornace e Canali di scorrimento del flusso d’aria calda, di materiale

refrattario assemblati in loco. descrizione • description

Funzionamento a gas, gasolio e combustibili solidi,“quali legna,

carbone, ecc.”

Our machines are designed, manufactured and assembled

in ITALY. - Le nostre macchine sono progettate, costruite e OPTIONAL

assemblate in ITALIA.

- Vaporizzatore supplementare per cella.

- Pratica fornace laterale perper il riscaldamento a combustibili solidi.

- Valvole a sfera - on/off - per la gestione manuale delle vaporiere.

Standard 3Ph - 50/60Hz - Apertura vetri verso il basso.

On request 220V - 1Ph - 50/60Hz - Apertura vetri verso l’alto con sgancio manuale As continued product improvement is a policy of MAC.PAN Srl, specifications are subject to change without notice.

192 193